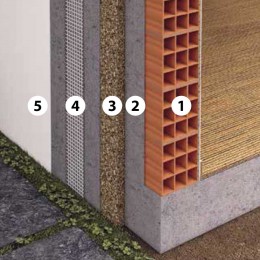

Applications

Cork and the thermo-acoustic insulation

The molecular structure and its chemical composition determine its characteristics which makes cork an excellent thermal and acoustic insulator. At cellular level, its tissue is composed of a very high number of tiny closed cells, separated each other by a very thin membrane, the thickness of which varies from 1.25 to 2.50 microns.

The cavities are filled with air and gas, mainly nitrogen, while the cell membranes are mainly made up of suberine and lignin, as well as various other waxy substances present, mostly, in negligible quantities.

These chemical-physical characteristics makes cork an excellent thermal and acoustic insulator. But how does cork works in insulation? It ‘s a very elastic material and this determines its absorbent capacity. In fact, a rigid material tends, when hit by sound waves, to give back a certain acceleration.

In cork this doesn’t happen. Since its cells are filled with air and gas, and with very thin membranes, once they are hit by some mechanical pressure, they adapt to the stress and then gradually return to their original state. The sound waves that hit the cells are slowly attenuated and the sound energy dissipated inside the material without being released outside. Here is the isolation and absorption of noise.

The aerial parts themselves, not communicating with each other, as closed cells, explain the excellent thermal insulation capacity. The heat from the room heats the air in the cell with which it comes into contact. In the absence of communication between this and the surrounding cells, the heat is transferred only in small quantities and so on, cell after cell. Therefore, an obstacle to the passage of heat is created and the temperature difference between the rooms separated by the cork is maintained.

In this section we present you some fiches with the main applications of cork in the construction field.